General Purpose Capacitors

General Purpose Capacitors Specification

- Loss Tangent

- 0.002 (at 1kHz)

- Breakdown Voltage

- >1.6 x Rated Voltage

- Insulation Voltage

- 2000V AC for 2 seconds

- Frequency

- 50/60 Hz

- Insulation Resistance

- >30,000 MF (at 500VDC)

- Lead Spacing

- Pin to Pin as per package

- Current

- As per application

- Product Type

- General Purpose Capacitors

- Material

- Plastic Film / Polymer

- Capacitance

- 2 mfd / 440VAC

- Shell

- Non-Metallic

- Operating Temperature

- -40C to +85C

- Rated Voltage

- 440VAC

- Ripple

- Low

- Capacitance Tolerance

- 5%

- Temperature Range

- -40C to +85C

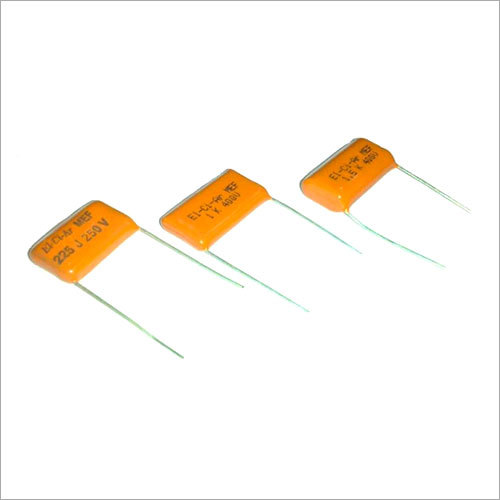

- Shape

- Rectangular / Box

- Terminal

- Radial Leads

- Application

- Fans, Air Conditioners, Lighting, Motor Run

- Size

- Standard/Compact

- Color

- Black

About General Purpose Capacitors

Offered General Purpose Capacitors are basically aluminum electrolytic capacitors that are used as important part of motorcycles. Equipped with steel made enclosure, these capacitors contain double lead cables that have colored ring tags. Precise shape, light weight and excellent vibration resistance capacity are the key characteristics of these capacitors. Advanced design of these general purpose automotive capacitors helps to improve performance of motorcycle especially while crossing road bumps. These low maintenance capacitors are simple to install and handle. Premium quality of these automotive products has been verified on the basis of their performance, service life and diameter. We are a prestigious supplier and manufacturer of General Purpose Capacitors.

Capacity: 0.320 uF

Cable: Red 335mm + 5.1 mm ring tag Yellow 135 mm + 3.8 mm ring tag

Size: 19.8mm DIA x 32mm L

Use:

- Bajaj Vespa 150 scooter

- Bajaj 150 scooter

- Girnar 150 scooter

- Priya 150 scooter (old)

- Narmada 150 scooter

Exceptional Durability and Safety Standards

Metallized polypropylene film capacitors offer superior moisture resistance and are flame retardant to UL 94V-0 standards, making them reliable even in challenging environments. These capacitors also comply with RoHS and leading international standards (IS 2993, IEC 60252-1, EN 60252-1). Their marking, made by laser, ensures permanent, legible identification throughout the products lifecycle.

Versatile Applications Across Multiple Industries

Engineered for general use, these capacitors perform excellently in fan, air conditioning, lighting, and motor run applications. Their compatibility with both standard and compact sizes, as well as various lead configurations, makes them a preferred choice for distributors, exporters, manufacturers, and suppliers throughout India and beyond.

Reliable Performance in Extreme Conditions

With an operating temperature range from -40C to +85C and storage up to +90C, these capacitors maintain consistent performance standards. They exhibit low ripple and loss tangent characteristics, high insulation resistance, and strong breakdown voltage, ensuring long service life and stable operation even under fluctuating loads.

FAQs of General Purpose Capacitors:

Q: How should metallized polypropylene film capacitors be stored for maximum longevity?

A: It is best to store these capacitors in environments where the temperature remains between -25C and +90C and moisture is controlled. Their excellent moisture resistance protects internal components, but stable storage conditions further enhance operational lifespan.Q: What benefits does a UL 94V-0 flame retardant grade provide for these capacitors?

A: Achieving UL 94V-0 accreditation ensures the capacitors enclosure has a high degree of flame retardancy. In the event of a fire, this limits the spread of flames, contributing to safer operation in electrical and electronic systems.Q: When should these capacitors be used in motor run or lighting applications?

A: Apply these capacitors when reliable phase correction, reduced power loss, and stable operation across a 50/60 Hz frequency range are required. Their low loss tangent and 5% capacitance tolerance ensure efficient and durable performance in motors and lighting circuits.Q: Where are these capacitors typically used within a system?

A: These capacitors are generally placed in fan circuits, air conditioners, lighting ballasts, and electric motors to improve power factor, reduce losses, and enhance load stability. Their radial leads and compact shape make integration straightforward in various assembly layouts.Q: What is the process for ensuring compliance with international capacitor standards?

A: Each capacitor undergoes rigorous testing and quality checks to comply with IS 2993, IEC 60252-1, and EN 60252-1 standards. Compliance with RoHS is achieved by controlling material content, ensuring environmentally friendly manufacturing and use.Q: How does laser marking benefit the identification and usage of these capacitors?

A: Laser marking provides durable and clear identification that will not fade over time, even in challenging environmental conditions. This ensures accurate tracking for inventory, installation, and maintenance, reducing errors in component selection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

NEOTRONIKS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry