MPP - Metallized Polypropylene Capacitors

MPP - Metallized Polypropylene Capacitors Specification

- Frequency

- Up to 100 kHz

- Breakdown Voltage

- 1.6 x Rated Voltage for 2 sec

- Insulation Voltage

- 2000V AC (for 2 sec)

- Insulation Resistance

- 20,000 M (at 500V DC, 1 min)

- Lead Spacing

- 5mm, 7.5mm, 10mm, 15mm or as per specification

- Surface Mount Land Size

- Not applicable (radial leads)

- Loss Tangent

- tan 0.001 (at 1 kHz)

- Current

- Application dependent

- Product Type

- Metallized Polypropylene Capacitors (MPP)

- Material

- Metallized Polypropylene Film

- Capacitance

- 0.001F 10F

- Shell

- Plastic/Resin Encapsulation

- Operating Temperature

- -40C to +105C

- Rated Voltage

- 100V, 250V, 400V, 630V DC

- Ripple

- Low ripple current

- Capacitance Tolerance

- 5% (J), 10% (K)

- Temperature Range

- -40C to +105C

- Shape

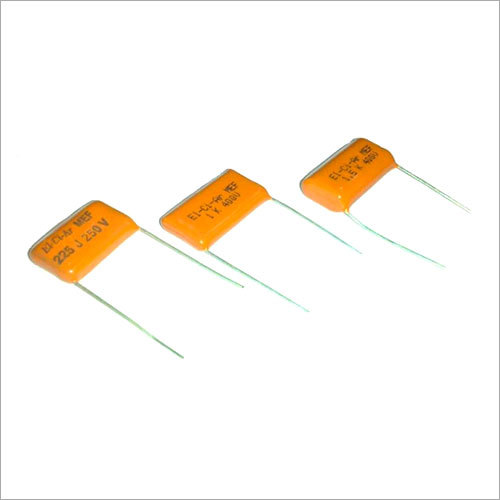

- Box type

- Terminal

- Radial leads (tinned copper wire)

- Application

- Power supplies, electronic lighting, pulse circuits, filtering circuits

- Size

- Custom/varies by capacitance and voltage

- Color

- Yellow (standard)

- Moisture Resistance

- Withstands up to 95% RH at 40C

- Packaging

- Bulk/Ammo pack/Tape & Reel (as requested)

- Self-Healing Property

- Present Metallized film provides self-healing capability

- Pulse Withstand Capability

- Excellent for high-frequency, high-current applications

- Flame Retardant Grade

- UL94V-0 compliant

- RoHS Compliance

- Yes

- Dielectric Strength

- 200% of rated voltage for 2 sec

- Dissipation Factor

- 0.1% at 1 kHz

- Voltage Proof

- 150% of rated voltage for 60 sec

- Storage Temperature

- -40C to +110C

About MPP - Metallized Polypropylene Capacitors

MPP Metallized Polypropylene

Construction:

MPP Capacitors are wound with Metallized polypropylene film as dielectric and copper clad steel wire and epoxy coating.

Features:

- Self healing properties

- Non - inductive construction

- Low Dissipation and High Moisture resistance

Test Method & Performance Endurance

Test Conditions

- Temperature : + 100C

- Test Duration: 2000 hours

- Voltage Applied: 1.25 x Vr

Performance

- Capacitance Change: 3%

- DF: 0.02% max

- IR: 50% of Initial Limit

Resistance to Soldering heat Test Conditions

- Solder Bath Temperature: + 260C

- Dipping Time: 10 sec max

Performance

- Capacitance Change: 2%

- DF: 0.01% max

- IR: Initial Limit

Specification:

| Reference Standard | IEC 60384-16 |

| Operating Temperature | -40C to + 100C |

| Capacitance Range | 0.01 uF, 2.2uF, & 3.3uF |

| Capacitance Tolerance | 5% (J), 10% (K) 20% (M) |

| DC Rated Voltage Vr | 100V, 250VAC, 400V, 630V |

| Dissipation Factor | 0.5% max at 1Khz, 2C |

| Dielectric Strength | 1.60 x Vr for 2 sec |

| Insulation Resistance at 100V and 25C | 100,000 M for C 0.33uF 10,000 sec for C 0.33 uF |

| Marking | El-Ci-Ar Logo, MPP, Capacitance, Tolerance, Rated Voltage, Batch No |

Superior Dielectric & Flame Retardant Performance

MPP capacitors stand out due to their dielectric strength, rated at 200% of the specified voltage for 2 seconds. Paired with UL94V-0 flame retardancy and a wide operating temperature range, they assure safety and resilience in demanding applications. This makes them a trusted choice for electronics requiring both robust voltage handling and flame safety certifications.

Exceptional Moisture and Temperature Resistance

With the capacity to withstand up to 95% relative humidity at 40C and function effectively from -40C to +105C, these metallized polypropylene capacitors maintain performance even in harsh or fluctuating environmental conditions. Their advanced encapsulation safeguards the internal elements, ensuring long-term reliability for industrial and commercial uses.

Versatile Application Compatibility

Available with radial tinned copper leads and multiple lead spacings, MPP capacitors easily integrate into varied circuits such as power supplies, electronic lighting, and high-frequency pulse or filtering systems. Their excellent pulse withstand capability and low dissipation factor provide stable operation up to 100 kHz, meeting the needs of modern, high-frequency electronic equipment.

FAQs of MPP - Metallized Polypropylene Capacitors:

Q: How are MPP Metallized Polypropylene Capacitors used in electronic circuits?

A: These capacitors are commonly used in power supplies, electronic lighting systems, pulse circuits, and filtering applications due to their excellent pulse withstand capability, low ripple current, and high insulation resistance. Their robust construction ensures stability and reliability over extended operation.Q: What benefits does the self-healing property provide for these capacitors?

A: The self-healing property, inherent to metallized film construction, allows the capacitor to restore its insulation after a minor breakdown. This extends its operational life, enhances reliability, and reduces the risk of circuit failure, making them preferable for critical or high-pulse environments.Q: When should I opt for a capacitor with UL94V-0 flame retardancy?

A: Select UL94V-0 flame retardant capacitors whenever your application requires high safety standards against fire hazards. These are essential in consumer electronics, industrial controllers, and lighting systems where flame resistance is mandated by safety regulations or operating environments are prone to electrical faults.Q: Where are these capacitors typically manufactured and supplied from?

A: These MPP capacitors are broadly manufactured and supplied in India, with distribution channels extending globally. They are available through bulk distributors, exporters, and direct manufacturers, catering to customized requests for size, lead spacing, and packaging.Q: What is the process for selecting the correct MPP capacitor for my design?

A: Start by identifying your required capacitance, rated voltage, operating frequency, and tolerance. Consider environmental requirements, such as humidity and temperature, as well as circuit-specific needs such as lead spacing and packaging type. Reviewing performance features like self-healing and insulation resistance will ensure optimal and safe integration.Q: How does moisture resistance benefit my application?

A: With the ability to withstand up to 95% relative humidity at 40C, these capacitors provide robust performance in damp or humid conditions, protecting against moisture-related failures and ensuring long-term durability in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallized Dip Capacitors Category

Polypropylene plus Double Metallised Paper Capacitor

Price 200 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Blue

Product Type : Capacitor, Other

Rated Voltage : 1000V DC

Breakdown Voltage : 1000V DC

Metallized Polypropylene Fan Regulator Capacitors - MKP11 (1uF - 4.3uF in 250VAC)

Price 3-10 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Grey

Product Type : Other, Metallized Polypropylene Fan Regulator Capacitor

Rated Voltage : 250VAC

Breakdown Voltage : 1100VAC (1 minute)

X2 Capacitors - MPX 300VAC

Price 1-30 INR / Piece

Minimum Order Quantity : 10000 Pieces

Color : Yellow

Product Type : Other, X2 Capacitors MPX

Rated Voltage : 300VAC

Breakdown Voltage : 1200VAC

Metallized Polypropylene

Minimum Order Quantity : 1000 Pieces

Color : Blue

Product Type : Other, Film Capacitor

Rated Voltage : 450 VDC

Breakdown Voltage : 6501100 V

|

NEOTRONIKS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry